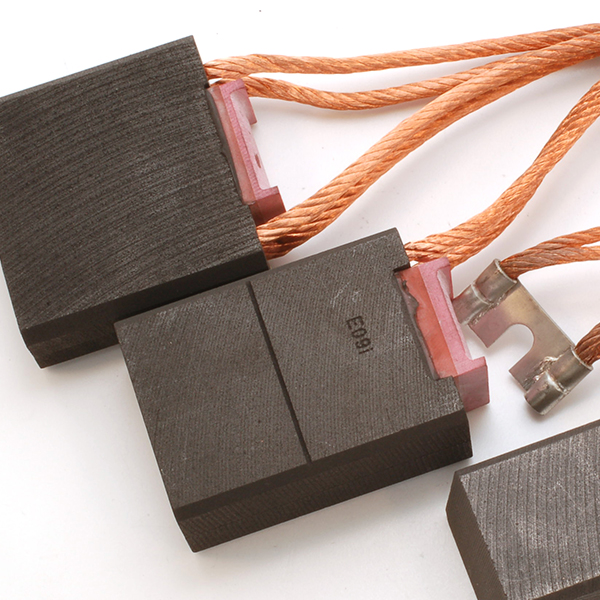

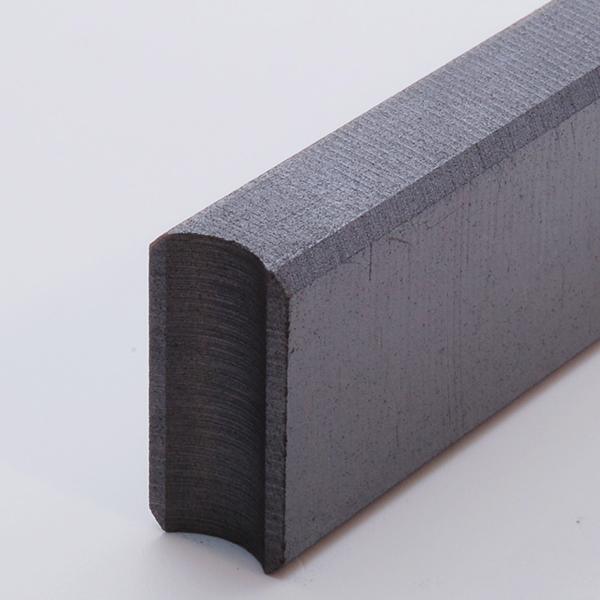

Carbon vanes

Description of carbon vanes

Carbon vanes have proved successfully as sealing elements in rotating compressors such as vacuum pumps and condensers of liquids and gases.

Advantages of our MEGA-vanes grades are very good self-lubrication, and the inferior specific density of artifical carbon, contrary to metal grade vanes. They are suitable for fast running pumps by low wear.

Based on experience, the leaving edges of the rotor slots must be chamfered or rounded, also the entering edges of the vanes, as to lower unwanted pressure, and thus guaranteeing an easier run-in.

Applications and customers of carbon vanes

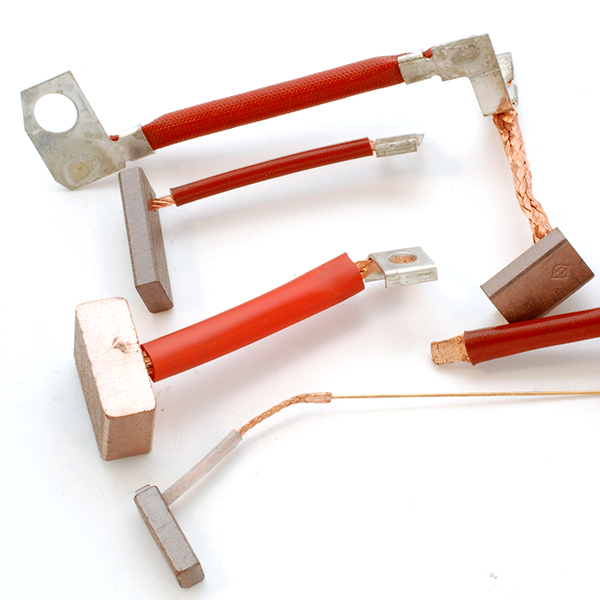

- compressors, pumps for air (gases) and liquids, application for sliding speeds up to 12 m/sec and up to pressure differences of 3 to 5 bar

- Grades: hard carbon and electrographite carbon for the Food industry, resin bonded grades for the NON-FOOD industry

Characteristics and service

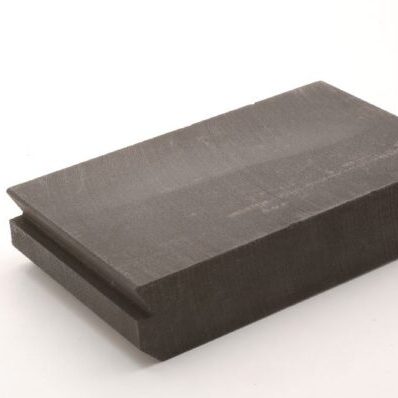

The life time of carbon vanes depends above all on a precise machining of the opposite sliding areas. For the slot machining we recommend a roughness depth of approx. 1µ and a slot tolerance of H8, the surface finish of the cylinder walls should have a roughness depth of <0,5 µ. Depending on customers’ requirements, shapes and grades can be realised and modified.