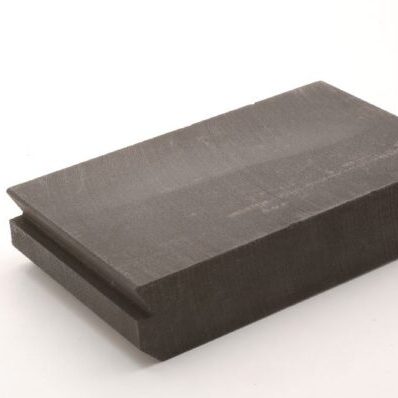

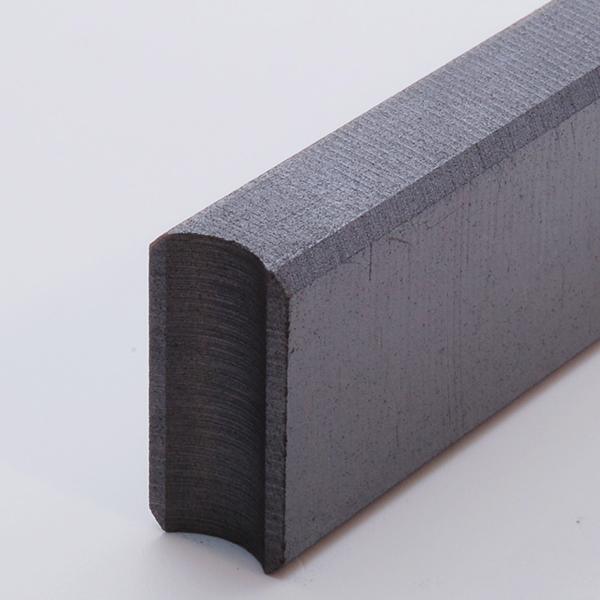

Industrial carbon brushes

Description of industrial carbon brushes

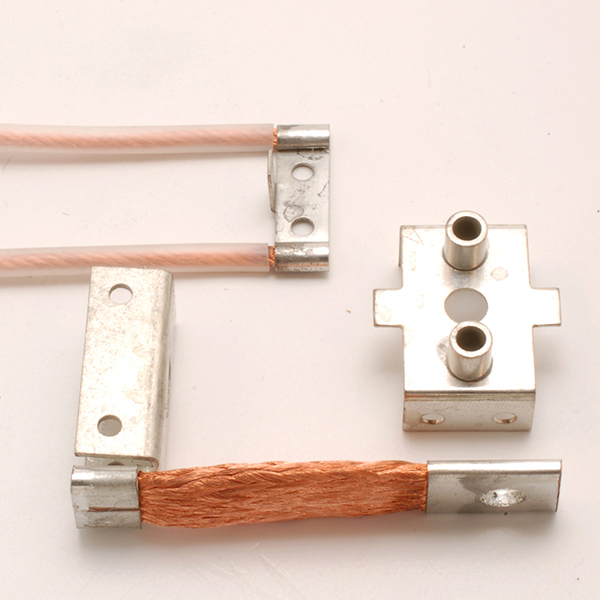

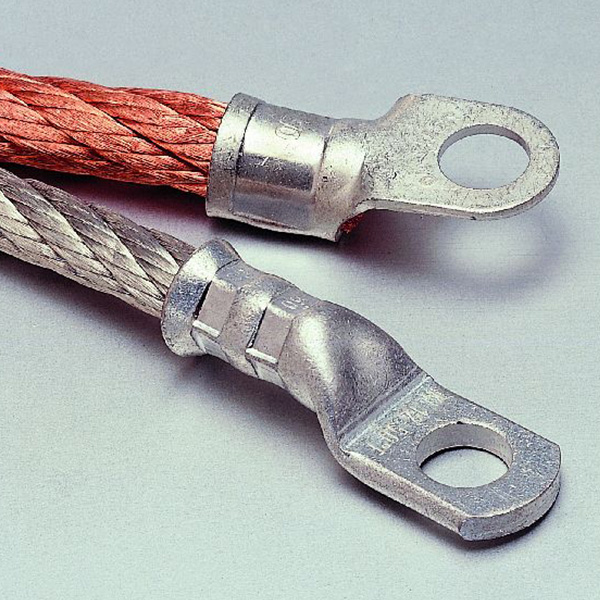

Industrial carbon brushes still have an extensive field of application on big and medium commutator machines with high electrical, thermique and mechanical duties. The range includes commutator equipment, slipring rotors, and other diversest current transmission systems.

The base is a wide product assortment of carbon grades of variable compositions. Thus different specific resistances, specific densities, hardness- and load conditions can be realized.

All these parameters obtained, allow an adaption of carbon brush grade to the needs of the motor-manufacturers and designers. Diversified application and field of operation determine the dimensions and shapes of our industrial carbon brushes.

Applications and customers

- DC and AC motors, generators, three-phase commutator motors, thyristor-controlled DC-motors, traction motors, variable speed-motors, exciting generators, rotor-feed shunt-wound motors, assyncronous motors, series-wound motors

- Trolley-busses, mine cars, tramways, steel-cement-paper mills, Schrage systems in the textile and plastic industry

- Steel slip rings in electrical power stations, on Turbogenerators, hydro-powerstations, wind mill power units

- power converters of all kind, frequency, converters, battery-driven cars, extruders, earthing systems for railway and ships, fork lift trucks, lifts, cablecars, mine winding units, cranes and lifting systems, pumps

- carbon grades for higher altitudes

- carbon brushes specially impregnated for dryatmosphere, supercooled rooms, aircooled motors

Special features and services

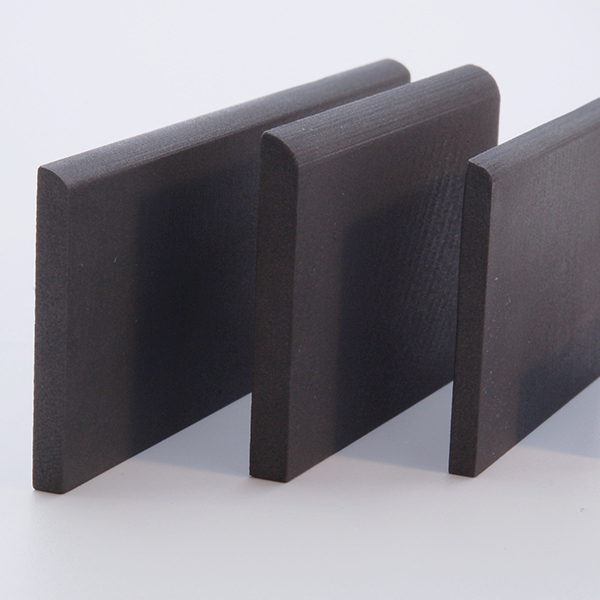

Industrial carbon brushess continue to be used extensively on large and medium-sized power converting machines with high electrical, thermal and mechanical loads. The range includes machines with collectors, slip ring rotors and a wide variety of power transmission systems.

The basis is a wide range of carbon materials with different compositions. This allows various specific resistances, densities, hardness values and load values to be realised. All these parameters make it possible to customise the carbon quality to the requirements of engine manufacturers and designers. A wide variety of applications and areas of use determine the dimensions and designs of our industrial carbons.